|

The DC100 Tape and Drive: Accidental Start of a New Industry

Clearly, the first- and second-generation desktop-calculator magnetic cards were grossly inadequate for the HP 9825 project. They had far too little capacity (measured in a few hundred program steps or data values). The modified Philips digital tape cassette used in the HP 9830A and 9821A desktop calculators and the HP 9865A tape drive was a bit better with 64 Kbytes of storage capacity (unformatted, about 42 Kbytes formatted), but it was far too slow. The HP 9825A’s expanded abilities called out for something much better than a souped-up audio cassette.

Today, with 20/20 hindsight, the right answer seems obvious: use a floppy disk drive! When we say that however we’re thinking of the 3.5-inch floppy, which is so old and obsolete that it’s just about to disappear completely from the PC scene. As transportable storage media, floppy disks have been supplanted by CD ROMs, DVDs, and flash-based USB drives that offer much higher capacity (hundreds of megabytes instead of 1.44 Mbytes) and much faster operation. But back in the early 1970s, there were no optical disk drives or solid-state flash memory. Alan Shugart’s team at IBM had just barely developed the first working 8-inch floppy disk drive as a microprogram loader for IBM’s 3330 disk pack file (a 100-Mbyte hard disk drive for mainframe computers). Unfortunately, IBM’s 8-inch floppy disk drive (circa 1971) was physically huge—much too large for the HP 9825A desktop calculator. Shugart had yet to invent the 5.25-inch floppy drive and Sony would not introduce the 3.5-inch floppy disk drive (which would probably have been small enough to fit in an HP 9825A) until 1981.

A QIC fix

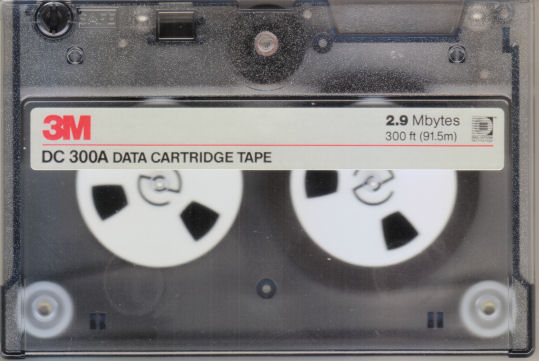

The HP Loveland desktop-calculator engineers cast about for another solution to the problem of mass storage. One possibility was the DC300 tape cartridge, introduced in 1972. The 3M Company had developed the DC300 tape cartridge for loading programs into AT&T’s electronic switching systems that were becoming the backbone of the world’s phone system back in the 1970s. The DC300 tape cartridge—originally just called the “3M Data Cartridge—used magnetic tape that was 0.25 inches wide and therefore became known as the “quarter-inch cartridge” (abbreviated as QIC, pronounced “quick”).

IBM introduced the model 5100 desktop computer using the DC300 tape cartridge in September, 1975—a few months before the introduction of the HP 9825A. The 55-pound IBM 5100 managed to swallow a 200-Kbyte DC300 tape cartridge, but IBM’s desktop computer was fairly large. In fact, it was much larger than the planned volume of the HP 9825A, which was hopelessly too petite to accommodate the relatively large DC300 tape drive in its slim, trim figure. IBM’s model 5100 also went on the market for $20,000—nearly four times the planned selling price for the HP 9825A. HP needed a smaller and cheaper mass-storage device for the HP 9825A than the DC300 tape cartridge and drive.

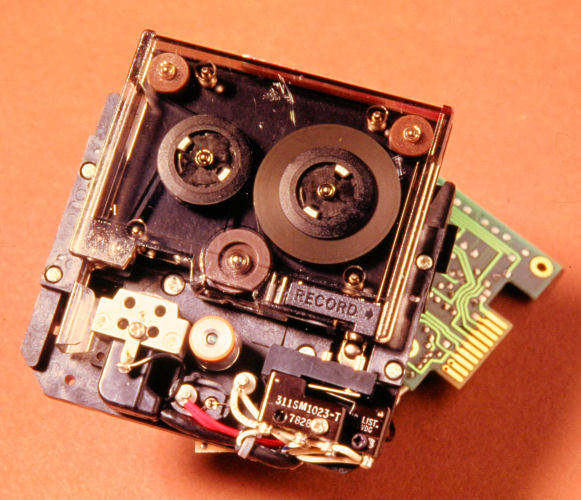

Consequently, HP partnered with 3M to develop a smaller version of the DC300 tape cartridge and drive. However, 3M didn’t devote much time or money to the project (in other words, 3M’s management didn’t smell money in the project and left it to self-fund on a pay-as-you-go basis) so HP engineers did most of the early work to shrink the DC300 tape cartridge and to develop a tape drive for the new, smaller tape cartridge. The tape-transport project was called FACT (Fast Access Cartridge Transport). The project team included Greg Vogel (mechanical engineer), John Becker (tape-drive electronics), Perry Pierce (tape cartridge mechanicals), Alan Richards (tape drive and system electronics), and Ken Heun (recording technology and firmware drivers). Alan Richards had worked on the tape-drive electronics of the HP 9865A tape drive. Perry Pierce, a mechanical engineer, modeled the mechanicals of the new tape cartridge. Chuck McAffee was the project manager. John Mahorney led the production engineering team.

|

|

|

DC300 Tape Cartridge

|

|

|

|

|

|

DC100 Tape Minicartridge (Not shown to scale with the DC300 tape cartridge)

Photo courtesy of Alan Richards

|

|

The resulting tape cartridge was called the DC100, the little brother to the DC300. Unlike the DC300, the DC100 used narrower tape (measuring 0.150 inches, although known as eighth-inch tape). It quickly became known as the mini data cartridge or just the “minicartridge.” The 3M Company manufactured the early DC100 minicartridges and quickly became a critical bottleneck due to low production volumes. The limited number of early cartridges produced by 3M actually restricted early HP 9825A sales because people wouldn’t buy the calculator if they couldn’t save their programs and data.

Although 3M had contractually agreed to let HP be a second source for the DC100 tape cartridge, it had not shared many of the proprietary fabrication methods required to manufacture the minicartridge. For reasons of profit and revenue, the 3M Company understandably wanted to remain HP’s sole source for the DC100 tape cartridge and so the company dragged its feet in helping its partner get up to speed. To deal with 3M’s benign neglect of the project, HP Loveland initiated a crash 5-month project named “Bullet” to develop the ability to manufacture copies of 3M’s minicartridge.

Reverse engineering

Some of the critical manufacturing-tolerance issues 3M chose to keep secret included the baseplate flatness, base plate flatness, precisely inserting the guide posts (essentially the 5 "axles" in the cartridge) into the base plate with sufficient perpendicularity, guide-post surface finish, and lubrication. In addition, 3M had not shared the secret process for making the cartridge’s internal plastic drive belt, perhaps the most critical component of the design. The tape-cartridge design team at HP embarked on a 5-month program to reverse engineer the drive-belt fabrication process so that HP could exercise its existing right to manufacture the DC100 cartridges. It wasn’t just HP’s 9825A that depended on a supply of the tape cartridges. The new HP 9815A desktop calculator and HP 2644A data terminal also used this cartridge so HP needed to become an alternate source for the DC100.

Although he was an electrical engineer, Alan Richards reverse engineered the process for manufacturing DC100 minicartridge drive belts. The drive belts for the tape cartridge start as a 5-mil-thick plastic washer with a 1-inch diameter. The washer is stretched on a metal mandrel and then heat treated to retain the stretched size. Reverse engineering the heat-treating temperature profile turned out to be the tricky part of the manufacturing process.

Guide-post finish was a big challenge too. If the guides were too rough, they abraded the back of the tape. You might think that smooth would be best. Richards thought so too, early on. But, if the guides are too smooth, the tape actually adheres to the guide through stiction, which causes speed flutter on the tape. Richards tried many different processes to get just the right finish: sandblasting, nickel plating, abrading/polishing in a vibratory tumbler with various media, etc. He eventually found a lapidary tumbler, a recipe of abrasive and burnishing compound, and a process duration that gave what he calls the "mama bear" of finishes—not too rough, not too smooth, just right.

Another big challenge was guide-post perpendicularity. If the posts tilted even a small amount, a differential tension developed across the tape. If bad enough, this differential tension caused a loss of contact between tape and head. Tolerance and alignment between the holes in the minicartridge’s base plate and the holes in the manufacturing fixture that held the posts when they were pressed into the baseplate was critical. The two most critical posts, the hub bearing or axle posts, had to be perpendicular to within approximately 1/3 of a degree.

Improving on 3M’s design

The HP engineers didn’t just copy the original minicartridge, they actually improved upon 3M’s original design. In the original 3M cartridge design, tape tension is controlled primarily by friction in two rollers that the belt loops around. The 3M minicartridge design controlled belt-roller friction (and hence the tape tension) with a very precise amount of STP lubricant on the bearing surfaces. Too little lubricant made the tension too high while too much lubricant caused the tension to be too low. HP’s design used larger axles and Teflon-filled plastic for the for the bearing rollers, which entirely eliminated the lubrication.

There were several other innovations in the cartridge as well. Minimum tape tension at the head was a little higher, yet the drive force to spin the drive puck was less. Shock performance was improved; cartridge life was almost three times higher, and was more consistent. The design provided optical sensing of cartridge in and write protect, as well as supporting the original mechanical sensing.

One other "innovation" was the addition of a small scraper to knock dust off the tape before it contacted the head -- great idea that seemed to give lower error rates in early tests. Unfortunately, later testing showed that debris built up on the scraper. If the tape was parked for a while after a long run, the debris bonded to the tape so a later production change eliminated the scraper.

|

|

|

DC100 tape cartridge and drive.

Photo courtesy of Fred Wenninger

|

|

In all, HP engineers developed 37 parts for the new cartridge during the 5-month project including seven injection-molded parts tooled by HP. The HP minicartridge went into production in HP Loveland's Components building in downtown Loveland where production floor space was available. Cartridge production quickly became a big business. In fact, within the first year after entering manufacturing, cartridge revenue amounted to several million dollars.

Greg Vogel designed and set up tape-cartridge production in HP’s downtown Loveland manufacturing building. Within a year, HP Loveland was producing 20,000 DC100 tape cartridges per month. Vogel then set up a duplicate manufacturing line in Singapore. By 1978, the Singapore operation was also manufacturing tape transports. Manufacturing completely moved to Singapore in the early 1980s to further increase production and take advantage of the production capability and lower costs there. This was in the 1980-81 timeframe; Don Ditommaso spent some time perfecting the processes at Singapore.

HP later developed the compatible DC200 tape cartridge that used a thinner magnetic tape and could therefore pack more tape into and store more data in a cartridge. All of the desktop calculators and computers and some of the test equipment introduced by HP in the last half of the 1970s used the diminutive, cost-effective DC100 and DC200 tape cartridges and drive.

Spawning an industry

However, these HP products were not the real mark of success for the developers of the DC100 cartridge. The DC100 minicartridge spawned an entire tape-backup industry because the minicartridge’s form factor was the perfect size for backing up PCs with integral hard disk drives. A minicartridge drive could be designed to fit into the same volume as a standard 3.5-inch drive bay and that form-factor compatibility had a major influence on the success of the tape format.

PCs with hard drives started to appear only a couple of years after IBM introduced the original PC and the early hard drives on these machines were somewhat unreliable. The industry needed a good backup medium and by that time, QIC minicartridges had evolved from a 250-Kbyte storage capacity to 40, 80, 120, and eventually 250 Mbytes. As the hard disk drives’ capacities grew, the tape cartridges also evolved and grew in capacity to keep pace.

EOT (End of tape)

Eventually however, tape evolution failed to meet the development pace of the hard disk drive. QIC-3230 tapes have 20-Gbyte maximum storage capacities today, which is no longer enough to keep up with today’s one-fifth- to half-terabyte hard disk drives. Consequently, the QIC industry, which spawned several tape-backup companies and many dozens of incompatible tape formats, has now dwindled to almost nothing. Go into a CompUSA or MicroCenter and you won’t find many tape cartridges, if any. Only a few years ago, these stores devoted many feet of shelf space to tape cartridges of various capacities and formats.

One of the QIC-minicartridge tape-backup companies that started and succeeded in the 1980s was Colorado Memory Systems (CMS). The company was started as an adjunct to Colorado Time Systems, a maker of sports timing and scoreboard equipment that was popular in many schools and aquatic centers. Bill Beierwaltes, who joined HP Loveland as a design engineer in the mid 1960s, left HP in 1974 and started Colorado Time Systems down the street in nearby Berthoud, Colorado. A few years later, Alan Richards joined forces with Beierwaltes to found Colorado Memory Systems, which specialized in minicartridge drives for PCs.

The new company eventually captured 78% of the US PC tape-backup business and 65% of that business worldwide. HP acquired CMS in 1992. Both Richards and Beierwaltes became serial entrepreneurs. Beierwaltes engaged in other tape-related ventures over the years, but Richards had reached his limit with tape after CMS. Neither Richards nor Beierwaltes is in the tape business any longer although both still reside in Colorado. Richards is now president of Vesta Technology and Beierwaltes is CEO of Colorado vNet.

Information on this page was developed from discussions with Alan Richards and Don Morris and from information provided by Greg Vogel.

|

|